In 2024, China's fresh cut flower cultivation area reached 350,000 mu

(approximately 23,333 hectares), with an output of over 20 billion stems and a

total retail market size of 210 billion yuan. It is a thriving, labor-intensive

industry with dense production areas and promising development prospects.

After harvest, fresh cut flowers must undergo multiple processes—such as grading, leaf and thorn removal, trimming, bundling, and packaging—before they can be sold. These steps require significant labor and are inefficient. Different flower varieties have varying grading standards, processing procedures, and packaging requirements, making equipment highly customized and mechanization challenging.

Dutch flower processing equipment boasts high automation and productivity, suitable for most flowers like tulips and roses. However, these machines are expensive, with a single set costing over 7 million yuan, making them impractical for China's small-scale flower cultivation enterprises.

An alternative mechanized solution for small-scale producers can handle trimming, leaf and thorn removal, and bundling but still requires manual packaging. The FL70 series fresh cut flower processing line by Yantai Equation Machinery falls into this category. It has been widely adopted by domestic flower growers and exported to many countries in Europe, America, and Southeast Asia.

However, as labor costs rise rapidly, the limitations of this solution become more apparent. First, manual grading and bouquet assembly are still necessary, requiring excessive labor. Second, the leaf and thorn removal machine applies significant force, which works well for sturdy stems like roses but can damage delicate herbaceous flowers.

To address these issues, after more than two years of research, Yantai Equation Machinery officially launched a new solution this year.

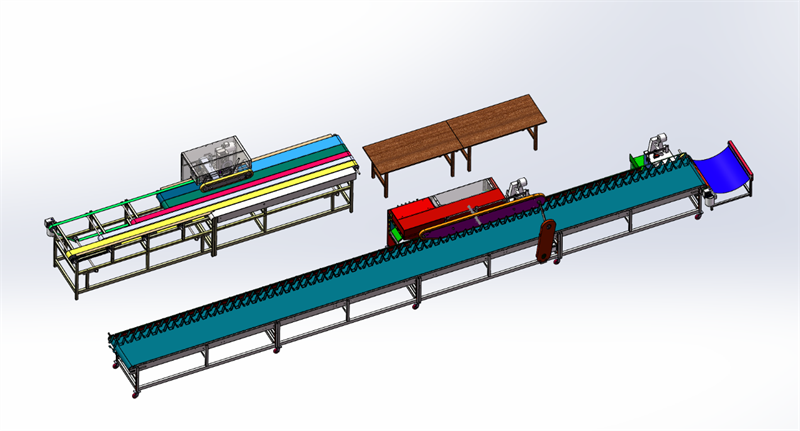

I. Equipment Composition

The main system consists of two units: a grading and bunching machine and a trimming and bundling machine.

· The grading and bunching machine includes:

o A fixed-length cutter

o A belt-type leaf remover

o A bunching mechanism

o One or two feeding platforms

· The trimming and bundling machine (a mature product of our company) includes:

o A trimmer

o A bundling machine

o A plastic flower sleeve rack

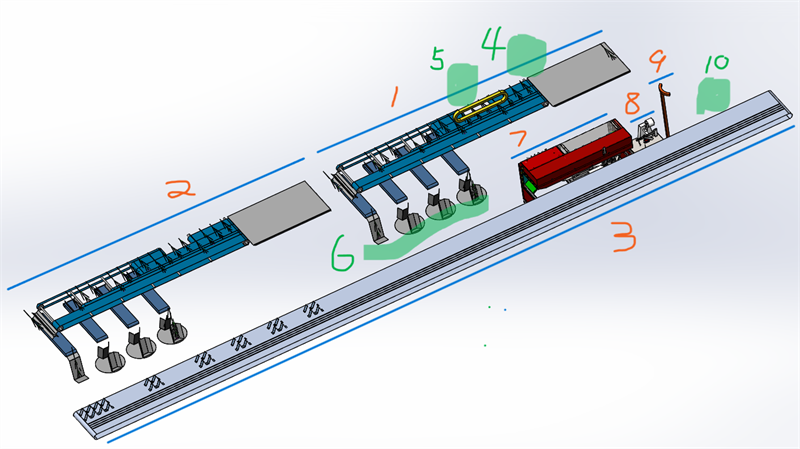

(See Figures 1 and 2 for illustrations. Figure 1 does not show the bunching machine; details are in Figure 2.)

Figure 1: Equipment Composition

Figure 2: Functional Diagram of the Solution

II. Working Principle

1. Grading

o Fresh cut flowers are placed on the feeding platform.

o 1–2 workers at Position 4 manually inspect and grade each stem before placing them on the conveyor belt of the grading machine.

o Primary grading criterion: length (e.g., for roses: Grade 1 ≥70 cm, Grade 2 ≥60 cm, Grade 3 ≥50 cm, Grade 4 ≥40 cm, Grade 5 <40 cm). Length standards must be confirmed before ordering and cannot be adjusted afterward.

o Secondary grading criteria: Bloom openness and disease presence. Overbloomed or diseased flowers are downgraded.

o The conveyor belt has marked lines—flower heads must align with the corresponding length grade.

2. Fixed-Length Trimming & Leaf/Thorn Removal

o At Position 5, a fixed-length cutter and belt-type leaf remover process the flowers.

o Stems are spaced ~20 cm apart on the conveyor.

o Excess stem length is cut, and leaves/thorns are gently combed off.

3. Bunching

o The bunching machine has an X-shaped flower cradle.

o Graded flowers move along the conveyor and fall into their respective cradles.

o A photoelectric sensor counts stems; once a set number (e.g., 10) is reached, the cradle rotates 90°, dropping the bunch onto another conveyor leading to Position 6 (buffer hopper).

o Flowers self-align head-down in the hopper, but stem ends remain uneven.

4. Transfer

o A worker at Position 6 moves bunches to the trimming and bundling machine’s conveyor, also marked with length grades.

5. Trimming & Bundling

o Bunches pass through:

§ A trimmer (Position 7) to even stem ends.

§ An elastic band bundler (Position 8) for automatic tying.

6. Sleeving

o At Position 9, a plastic sleeve rack is installed.

o A worker at Position 10 sleeves each bunch and sorts them by grade.

7. Packaging (Optional)

o If corrugated packaging is needed, 3–5 workers at Position 6 handle this step.

III. Functional Adaptability & Productivity

Due to variations in flower types and processing methods, this solution requires customization based on user needs.

Key Innovations:

· A new belt-type leaf remover replaces high-speed roller brushes, ensuring gentle treatment ideal for high-value delicate flowers (e.g., tulips, lilies).

· First-ever mechanized grading & bunching solution, addressing a major industry challenge.

Efficiency:

· 3,600 stems/hour (single machine).

· 7,200 stems/hour with dual grading machines.

Labor Savings:

· 3–4 workers for grading/feeding.

· 1–2 workers for transfer.

· 1 worker for sleeving.

This solution significantly enhances productivity while reducing labor dependency, making it a game-changer for the fresh cut flower industry.